Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

For the reinforcement of beams with normal sections, the time delay of bending failure decreases greatly, but it is still more ductile than shear failure. Therefore, the shear failure of CFRP strengthened beams should be avoided.

There are two main types of reinforcement for oblique section of beams. First, the shear capacity of the original concrete beam is insufficient. Secondly, the shear capacity of the oblique section of the beam is insufficient due to the reinforcement of the normal section.

For the reinforcement of beams with normal sections, the time delay of bending failure decreases greatly, but it is still more ductile than shear failure. Therefore, the shear failure of CFRP strengthened beams should be avoided.

Previous tests have shown that the shear capacity of flexural strengthened beams is hardly affected by the carbon fiber bonded on the bottom of the beams. Therefore, when calculating the bearing capacity of the inclined section of the beam, the influence of carbon fibers bonded to the bottom of the beam is neglected.

Reinforcement Method of Inclined Section of Carbon Fiber

Fiber orientation is generally arranged along the direction that can effectively control shear cracks. For shear strengthening of oblique cross-section of beams, there are three main methods of bonding carbon fibers:

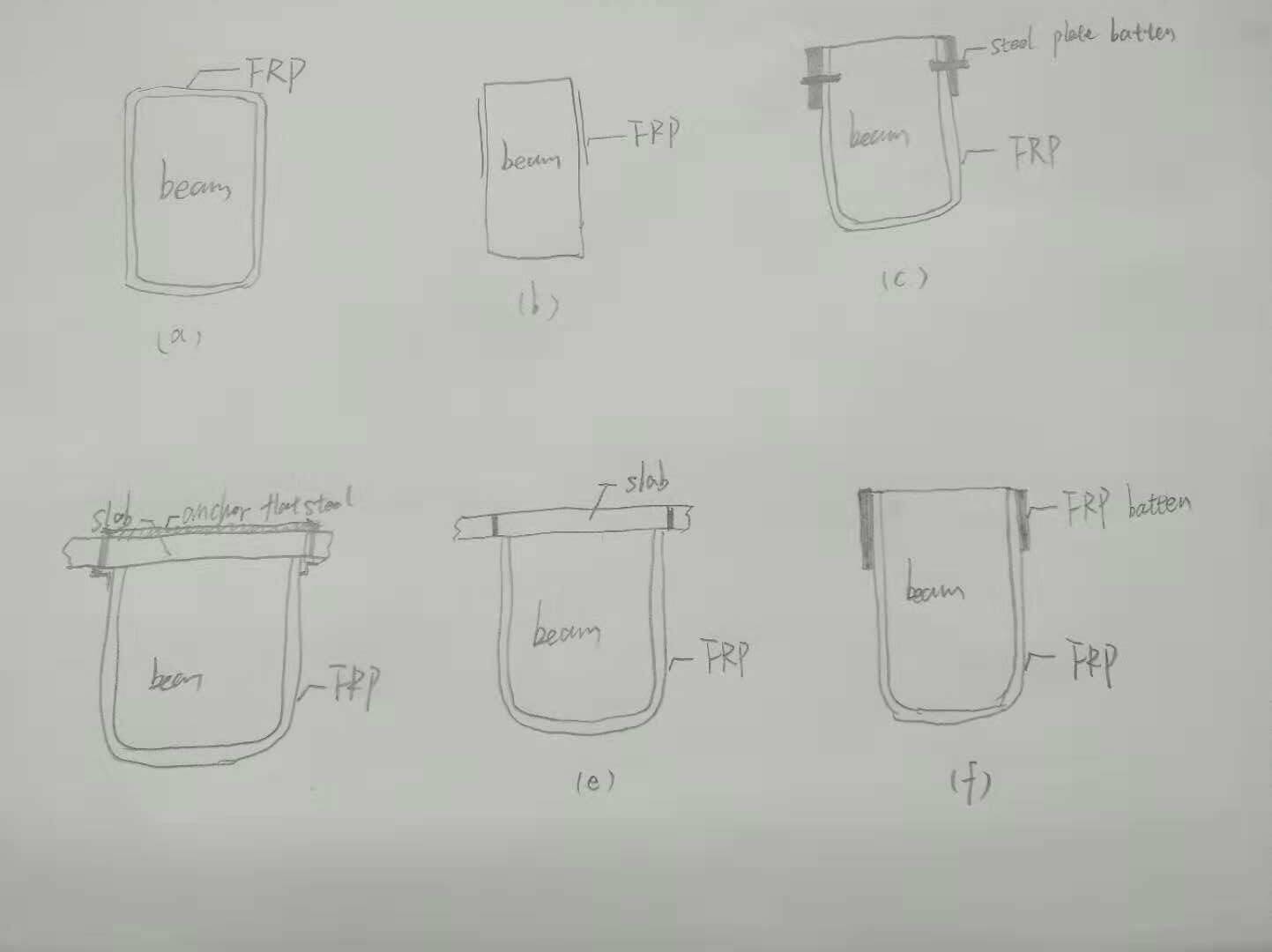

1. Closed encapsulation of carbon fiber strips across the whole beam section is the most difficult method to peel off and the best reinforcement effect is shown in the following figure (a). However, in most cases, the beams and floors are poured in one piece and can not be encapsulated in a closed way. This method has a small scope of application.

2. Stick carbon fibers on both sides of the beam. As shown in the following figure (b), this kind of method is easy to be peeled off, and the shear capacity is not improved much, and the reinforcement effect is the worst. It is not suitable to adopt this method in general.

3. Stick carbon fiber strips on the side and bottom (three sides) of the beam, i.e. U-shaped hoops, as shown in Figure C-F above. This kind of reinforcement method has a good effect and is widely used, but it may be peeled off at the free end of U-shaped hoop and needs to be anchored at the end. Longitudinal stripping is the commonly used anchorage method at present, as shown in the figure below.

Although all three methods can improve the shear capacity of oblique section of beams, the complete wrapping section is the most effective, followed by U-shaped wrapping, and the sticking effect on both sides is the worst. At present, enclosed wrapping or sticking U-shaped hoop are commonly used in engineering.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.