Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

sluice repair and reinforcement, carbon fiber sheet, planting bar technology

Due to the continuous advancement of science and technology, in the field of engineering construction, new technologies, new processes and new materials are also constantly emerging. These "new methods" have played a great role in the maintenance and reinforcement of sluices. In the following, we will introduce several "new methods" for repairing and strengthening different parts of the sluice in combination with engineering examples for reference.

1 Carbon fiber sheets strengthen and repair the concrete structure of the sluice

Reinforcing concrete structures with carbon fiber sheets is a new application of externally bonded high-performance composite materials to strengthen structures. It sticks the carbon fiber sheet to the surface of the component through a matching bonding material, so that the carbon fiber sheet can bear the tensile force, coordinate with the deformation of the concrete, and bear the force together. Carbon fiber materials have the characteristics of high strength, high modulus of elasticity, light weight and good corrosion resistance, which determine that their reinforcement repair technology is convenient and fast to construct, does not increase the load during reinforcement, has ideal effects, and saves subsequent maintenance. These are especially suitable for strengthening and repairing the concrete structures of coastal sluices along the river that were built in the 50-60s of the 20th century in our city and adopted low design and construction technical standards.

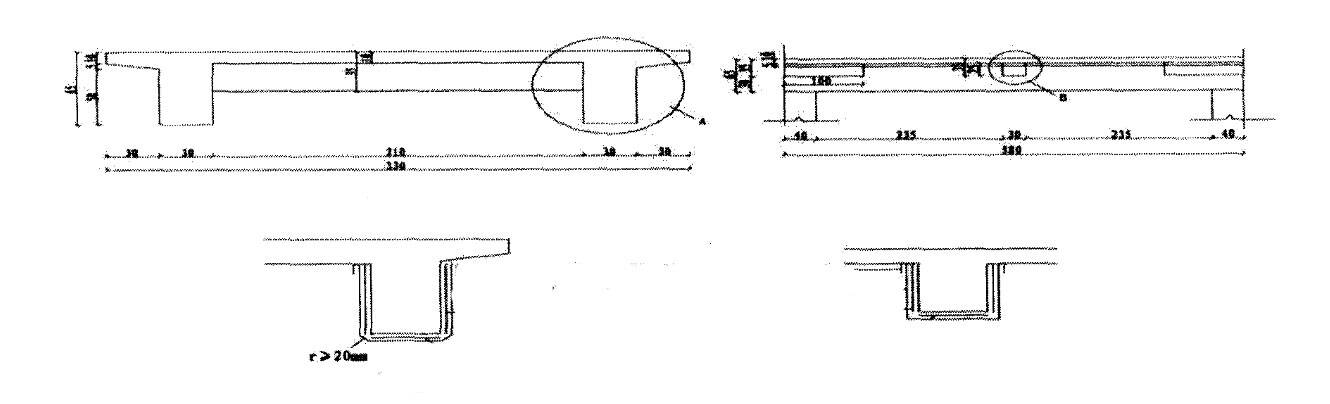

In recent years, the concrete repair and reinforcement of Qidong sluice has adopted a carbon fiber sheet reinforcement scheme, which has achieved good results. For example, the Honggangzha working bridge is reinforced. The working bridge is a cast-in-place T-beam structure, and there are different degrees of cracks and even ribs at the ribs and diaphragms. After a variety of technical and economic comparisons and combined with the specific conditions of the project, it was decided to use carbon fiber sheets to reinforce. The working bridge reinforcement plan is shown in Figure 1.

The specific method is as follows: the surface of the concrete is coated with the underlying resin and leveled. A carbon fiber sheet is pasted in the tension zone of the T-shaped beam and the transverse diaphragm for bending reinforcement, and the fiber direction is consistent with the tension direction of the reinforcement. The T-beam and the diaphragm are reinforced by shearing with closed paste and U-shaped paste, and the fiber direction is perpendicular to the axial direction of the component, and finally the surface is protected. After several years of operation, the reconstructed working bridge has achieved good results and fully achieved the purpose of strengthening and reconstruction.

2 Underwater non-dispersible concrete repairs the apron and ocean floods upstream and downstream of the sluice

The energy dissipating and anti-scouring projects of the sluice, such as the stilling pool, the stilling threshold, the apron, the sea flood, etc., are often damaged by scouring when the water is discharged. If not protected in time, the main safety of the sluice chamber will be endangered.

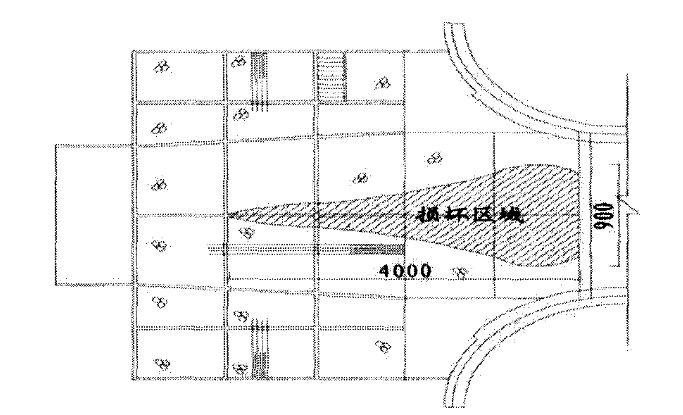

For the damage of the energy dissipation and erosion prevention works of the sluice, it is generally adopted to close the sluice hole and build a cofferdam to repair it. However, most coastal sluices along the Yangtze River in Qidong are navigable sluices, which do not have the ability to temporarily close the sluice sluice hole and build a cofferdam for maintenance. The underwater non-dispersible concrete is not limited by water depth, construction surface, concrete volume, nor affected by tidal water, and is suitable for various underwater concrete projects. The downstream part of the Touxing Port Gate in Qidong is affected by ship navigation and perennial water release, and has various degrees of damage. The damage is shown in Figure 2 (the downstream part of the Touxing Port Gate is damaged).

In view of the specific conditions of the Touxing Port Gate, the downstream damaged parts of the floodgate were treated with C25 underwater non-dispersible concrete after foundation cleaning. Underwater non-dispersible concrete is C25 concrete mixed with UWBII type underwater non-dispersant. The specific methods are: underwater foundation cleaning, gravel cushion and leveling, and underwater non-dispersed concrete pouring. The use of underwater non-dispersible concrete to pour energy dissipation and erosion prevention projects such as ocean floods has the advantages of convenient, fast, economical, reliable quality, safe and environmentally friendly underwater construction.

3 Application of planting bar technology on the joint surface of new and old concrete of sluice

The interface between new and old concrete is a weak link, and its interface bond strength is generally lower than that of integrally cast concrete, which greatly affects the reliability of repair and reinforcement structures. In order to make the new and old concrete form a common force, implanted shear steel bars have been increasingly used at the junction of the new and old concrete.

The wall of the stilling pool on the east side of the sluice downstream of Wangjiang Village, Qilong Township, Qidong City suddenly collapsed, and the wall of the stilling pool on the west side was also obviously inclined outward, and the wall was piled up at the gate, which made the sluice unable to operate normally. If it is not repaired in time, it will affect the lock chamber and downstream wing wall. Once the danger spreads and the lock body collapses, it will also affect the safety of the entire Qilong Township during the flood season. At the same time, it was in the main flood season, high tide level and frequent typhoons. In order to ensure the integrity and safety of the restoration project, the stilling pool walls were rebuilt on the east and west sides, and new and old concrete reinforcements were planted.

Conclusion

The repair and reinforcement technology of the sluice has significant economic benefits in terms of my country's national conditions and local finance. Therefore, it is of great practical significance for the promotion and application of "new methods" that can ensure project quality, reduce project costs, save labor consumption, shorten construction period and reduce pollution, and improve comprehensive economic effects.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.

Two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package for anchoring