Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

The key point of crack repair works is to design according to the types of cracks, determine the repair materials, repair methods and repair time.

The key point of crack repair works is to design according to the types of cracks, determine the repair materials, repair methods and time.

1.Classification of structural cracks:

(1) static crack

It is a crack caused by past events and forms, sizes and quantities that have stabilized and no longer develop. Its characteristic is that the width and length of the crack are stable. The materials and methods used in the repair are only related to the thickness of the cracks, but nothing to do with the rigidity or flexibility of the material.

(2) active cracks

It is the crack width and length that can not keep stable under the existing environment and working conditions. It is easy to crack, such as temperature crack, when the force, deformation of the structural member, or the temperature of the environment change. When repairing, it is necessary to eliminate the cause of its production, and observe for a period of time to confirm that it is stable and then repaired according to the treatment method of static crack. When it is not completely eliminated, but when the safety of structure and component is not harmful, it can be repaired with elastic and flexible materials.

(3) unstable cracks

It is the crack whose length, width or quantity is developing, but will be terminated after a period of time. For such cracks, they should be repaired or reinforced after general development, such as dry shrinkage cracks of concrete.

(4) non repairable cracks

Its width and length can not be kept stable, and the cracks will widen and grow as time goes on. If the reinforcement cracks along the longitudinal direction of the reinforcing bar, no matter how thin the crack is, it will continue to develop.

2, crack detection

(1) length: steel ruler measurement, generally locating the crack length by straight distance from both ends of the crack.

(2) width: measured with steel ruler, crack card and crack reading magnifying glass. The width of the crack is generally located at the widest point of the crack.

(3) depth: using the method of drilling, drilling core observation, ultrasonic method, filling color liquid and so on, the crack depth is generally located from the distance from the crack of the component to the maximum vertical depth.

(4) the development of cracks: the development of cracks on the component can increase the number of cracks, increase the length and width of the cracks, and determine the redevelopment of the cracks.

(5) length change monitoring: at both ends of the crack, the line is marked as the end point of the crack, the observation date is recorded on the side, and the endpoint is observed regularly if the crack is extended, and if it is extended, the crack is changed.

(6) width change monitoring: marking the widdest part of the observed cracks or installing a micrometer bearing, regular observation, if the width of the crack increases, it indicates that the crack is changed.

3. Common repair methods for cracks

(1) surface sealing method

The repair glue with low viscosity and good permeability is absorbed by fine independent cracks on the surface of concrete (the width of the crack width Omega 0.2mm) or the capillary action of the net cracks. For floor and other impervious parts, fiber composite should be pasted on the concrete surface to enhance the sealing effect.

(2) injection method

With a certain pressure, low viscosity and high strength repair glue is injected into the fracture cavity. This method is suitable for the independent cracks, penetrating cracks and the reinforcement and sealing of the local defects of the honeycomb like 0.2mm < 1.5mm.

(3) pressure grouting method

Within a certain period of time, the low viscosity and high strength grouting material used for repairing cracks is pressed into the fracture cavity with higher pressure to achieve the effect of filling dense. This method is applicable to the treatment of large penetrating cracks, mass concrete defects and deep and winding cracks.

(4) filled closed method

On the surface of the component, the groove depth and the groove width are not less than 20mm and 15mm U groove. Then the modified epoxy resin or elastic filling material is used to fill and paste the fiber composite material to seal the surface. This method is suitable for dealing with active cracks and static cracks of omega-0.5mm. After filling, the surface should be the protective layer.

4, crack repair material

(1) synthetic resins; (2) epoxy adhesive; (3) inorganic cementitious materials; (4) fiber reinfroced polymer(FRP) composite materials.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

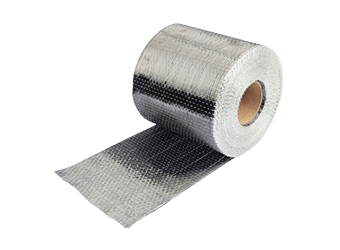

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

Very strong penetration and low viscosity epoxy crack injection adhesive for repairing concrete crack