Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

concrete bridges reinforcement

With the continuous expansion of infrastructure construction in my country in recent years, the level of domestic urbanization has continued, and people's travel needs have become increasingly abundant, and a large number of new bridges have appeared. At the same time, some bridges, due to increased load, unreasonable design, irregular construction process, and failure to do well in the later maintenance, cause bridge components to crack, and the bearing capacity of the bridge decreases. The method of bridge reinforcement is generally divided into changing the bridge force system and not changing the bridge force system.

1 The method of not changing the bridge force system

1.1 Grouting to repair cracks

The diseases of the upper components of the bridge are generally irregular cracks or excessive cracks. For small cracks (the crack width is 0.1~0.15mm), the pressure grouting repair method is commonly used in China. First, the cracks are treated in time, and then the specific pressure device is used to inject the concrete grout on the component cracks to realize the rapid repair of the cracks . For the treatment of large-area cracks, the domestic generally chooses to remove the loose and worn concrete, and then use the same grade of concrete for pouring and filling, so as to achieve the reinforcement effect.

1.2 Outsourcing reinforced piers

The common diseases of lower bridge components such as bridge piers are weathering of bridge piers and concrete spalling. In this regard, the method used in China is to strengthen the bridge piers. The method is to remove the weathered and peeling concrete outside the bridge pier, repair it with epoxy resin, reinforce it with steel plate outside, and finally pour the slightly expansive concrete. Foreign countries have also used similar methods to strengthen the piers. The difference is that after the concrete is removed, the bridge chooses to install sleeves and spray concrete that meets the design mix. This shows that the pier outer reinforcement method has practical construction significance.

1.3 Increase the force section

In actual engineering, increasing the force section is often used as a method of bridge reinforcement. In this method, new concrete is poured on the top or low surface of the flexural component and supplemented with corresponding steel bars to increase its bearing capacity and stiffness or change its natural frequency.

When the added concrete is in the tension zone, the main effect of reinforcement is the newly added steel bars, and the concrete only needs to be responsible for bonding and protecting the added steel bars. When the concrete of the supplementary layer is in the compression zone, the number of steel bars can be appropriately reduced to improve the economy. Because in this case, the role of concrete is to increase the effective height of the bending member, thereby increasing the bending and shearing resistance of the member, and increasing the rigidity of the member. Therefore, this reinforcement effect is good. However, the reinforcement method of increasing the cross-section of the concrete beam takes a long time, which has a greater impact on the nearby living and traffic, and reduces the headroom of the bridge.

1.4 CFRP reinforcement technology

Carbon fiber sheet (CFRP) is a kind of reinforcement material that has the advantages of light weight, high strength, simple operation, easy to stick, and no corrosion. The pasted carbon fiber sheet can be used for various forms of reinforcement such as bending resistance, shear resistance, compression resistance, eccentric compression, and earthquake resistance. This method is suitable for bending and shear strengthening of concrete beam bridges and slab bridges. For old bridges with insufficient bearing capacity due to low reinforcement ratio and severe steel corrosion, the reinforcement effect is more significant. It should be noted that when using this technology to reinforce the bridge, the environmental requirements proposed by the supplier must be met, such as the temperature and humidity of the carbon fiber sheet and the binder.

The carbon fiber sheet still presents an obvious linear elastic relationship when it is tensioned until it is broken. The difference between the ductility of the carbon fiber sheet and the steel bar is that the carbon fiber sheet is a brittle material. The above results in the need to restrict the use of carbon fiber materials. First, carbon fiber sheets are not as ductile as steel bars, and the ductility of the reinforced structure needs to be restricted. Secondly, due to the lack of ductility of the carbon fiber sheet, the redistribution of stress in the component will be restricted.

Therefore, in the structural design of pasting carbon fiber sheets, carbon fiber sheets cannot be simply used as a substitute for steel bars, and the brittleness of carbon fiber sheets must be considered.

2 The method of changing the bridge force system

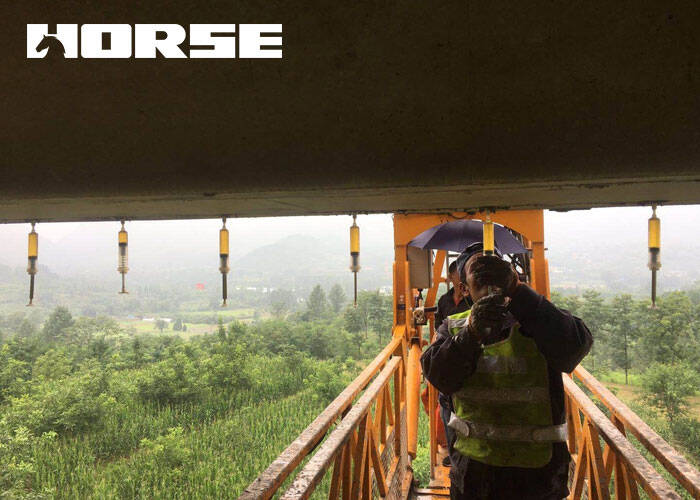

2.1 External prestressed reinforcement method

The external prestress reinforcement method is an unbonded prestress application method in which the prestressed tendons are arranged outside the main structure of the bridge or in the concrete box girder body without the need for grouting. It is different from the common prestressed concrete in the non-cohesiveness of prestressed tendons and concrete.

Due to the convenient, economical and reliable external prestress technology, construction can be carried out without affecting the passage of the bridge deck, and the construction operation is simple and flexible. Simply adding prestressed tie rods can strengthen the bridge and increase the number of statically indeterminates of the reinforced structure, thereby improving the overall safety of the structure. Moreover, the original bridge structure is not destroyed, and only strengthened on the original basis, so it is safe and reliable. High-strength steel can be fully utilized in this method, has good economy, and does not increase the cross-sectional size and weight of the structure.

However, the external force tendons are easily damaged, flammable, and subjected to vibration, which limits the development of the free length of the external force tendons. Secondly, the anchoring area and the steering block bear huge local stress, and the beam in the anchoring area of the prestressed tendons must be large cross-section or reinforced. The actual eccentricity of the external force bar applied in the external prestress reinforcement method is small, and the reverse bending moment generated under the same prestress is not as good as that of ordinary prestressed concrete, which leads to the bending resistance in the ultimate state is less than that of ordinary prestressed concrete . The externally prestressed structure may fail without warning due to insufficient ductility in the limit state.

The applicable conditions of the external force reinforcement method are.

1) It is suitable for situations where the flexural bearing capacity of the beam section is insufficient or the reinforcement in the tension zone is corroded.

2) It is suitable for situations where the beam deflection caused by insufficient beam stiffness exceeds the specification or the width of the crack in the tension zone exceeds the specification.

3) It is suitable for situations where the shear capacity of the oblique section of the beam is insufficient.

2.2 Replacement method

In some bridges, due to irregular construction process and other reasons, the bridge bearings are aging and damaged, or due to unreasonable design, the bridge bearings are set up incorrectly from the beginning. The above two reasons cause the bridge itself to be subjected to greater stress, which affects the bearing capacity and durability of the bridge. Projects at home and abroad, for example: a steel truss bridge in Perugia, Italy. The abutments and piers of the original truss bridge are all concrete structures. Movable bearings are installed on the abutments and fixed bearings are installed on the piers. After replacing the bearings on the steel truss bridge piers with rubber bearings. The first-order modal natural frequency of the bridge is reduced to 1.37 Hz. It can be seen that replacing the bearings can increase the bearing capacity of the bridge and reduce the natural frequency of the bridge.

2.3 Temporary loading on the bridge

For some bridges, the design and construction of the structure itself is reasonable and there is no obvious disease, but due to the need to pass special equipment and other reasons, the structure needs to be temporarily loaded. The “bridge on the bridge” structure can be used in engineering. The “bridge on the bridge” refers to the temporary load-sharing facility of laying prefabricated highway steel bridge on the original bridge structure to reduce the load of the superstructure. At the same time, the approach bridge was erected at both ends of the paved steel bridge. The method has simple construction and can improve the bearing capacity of the bridge, so that heavy loads such as special equipment can pass the bridge smoothly. Moreover, it is convenient to dismantle and will not have a major impact on the structure of the bridge.

3 Reinforcement principle

There are many ways to strengthen bridges as mentioned above. For specific engineering selection, the principles that should be followed are as follows.

1) Before deciding on a reinforcement plan, comprehensive consideration must be made from the resources and time consumed, the impact on traffic, whether it is technically feasible, and the impact on durability.

2) By increasing the cross-section or repairing cracks in bridge components, the bearing capacity of the local or entire bridge can be improved. Therefore, the principle of general bridge reinforcement work is to not change the original structure of the bridge as much as possible. In the case of economic considerations, only when ordinary reinforcement methods can not meet the requirements, consider changing the structural form. If the method of reinforcement and reinforcement still fails to meet the transportation requirements, part or all of the bridge must be rebuilt.

3) When selecting the bridge reinforcement method, the current status of the old bridge, the degree of reduced bearing capacity, and the future traffic volume must be considered. It is best to refer to the construction of the bridge that has been successfully reinforced.

4) Before using the method of enlarging or increasing the cross-section of bridge members for reinforcement, the combined effect of the added part and the original part should be considered.

4 Conclusion

The repair and reinforcement of bridges is a topic of general concern all over the world. In the past, a large number of bridges were built in our country, but the maintenance of the bridges was not in place, causing some bridges to appear prematurely and fail to meet the design and use requirements. While the construction of new bridges in China is in full swing, we should also start to pay attention to the maintenance and reinforcement of old bridges, and adopt a variety of reinforcement methods to improve the bearing capacity and service life of the bridge. The reinforcement method needs to meet the principles of simple construction, cost-effectiveness, and minimal interruption of traffic. Until today, the inspection, maintenance, and use of bridges have not yet formed a complete system, resulting in bridge reinforcement progress lagging behind bridge diseases. Therefore, the daily maintenance and inspection of the bridge should be done well, and the preventive maintenance of the bridge should be done to reduce the bridge disease.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.