Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Shear performance of reinforced concrete beams strengthened with carbon fiber cloth and steel wire rope

Passive reinforcement-carbon fiber wrap reinforcement

Fiber-reinforced polymer composite (FRP) is a new type of high-performance material that is composed of fiber-reinforced materials and resin matrix materials mixed in a certain proportion and combined through a certain process. Since the advent of this new material in the 1940s, it has been widely used in aviation, aerospace, shipbuilding, automotive and chemical industries. The advantages of FRP composite materials are mainly high strength, light weight and corrosion resistance, so it also has a wide range of application prospects in civil engineering. As a passive reinforcement method, FRP composite materials are pasted to improve the shear resistance of reinforced concrete beams/columns. The main methods include side pasting, U-shaped pasting and full-wrap pasting.

Active reinforcement-wire rope reinforcement

External prestress is a type of prestress corresponding to the traditional bonded and unbonded internal prestress, and it is also one of the branches of the post-tensioned prestress system. The main process is to arrange external prestressed steel wire strands or steel strands on the surface of the concrete structure, and apply external prestress to the concrete structure through manual tensioning, and then strengthen the concrete structure. Using this active reinforcement method can offset part or all of the self-weight stress of the concrete structure, play a role of unloading, and thus can effectively improve the bearing capacity of the concrete beam. Externally prestressed steel wire rope shear reinforcement can effectively improve the shear capacity of concrete beams. The shear capacity of reinforced concrete beams increases with the increase of the concrete strength level, and changes linearly.

In conclusion

Based on two methods of steel wire rope and carbon fiber cloth reinforcement, the shear reinforcement effects of reinforced concrete beams are compared, and the arrangement spacing and arrangement method of steel wire ropes, as well as the influence of the number of layers of carbon fiber cloth and the bonding method on the shear reinforcement effect are analyzed respectively. The main conclusions are as follows:

(1) It can be seen from the graded loading of the comparative test beam and the reinforced test beam that the failure modes of all concrete beams are typical shear failure;

(2) Considering the influencing factor of the different layout spacing of the steel wire ropes, the three different spacings have significantly improved the shear bearing capacity of the concrete test beam. As the layout spacing increases, the magnitude of this increase gradually decreases, but it still exceeds the cracking load of the comparative concrete beam. The measured cracking load of the concrete beam with an oblique 45° opening arrangement is less than that with a closed U-shaped hoop arrangement, which shows that the cracking performance of the reinforced beam with a closed U-shaped hoops arrangement is better than that of a reinforced beam with an oblique 45° opening. In practical engineering applications, U-shaped steel wire ropes with smaller spacing should be used to reinforce the shear capacity of concrete beams;

(3) The maximum shear bearing capacity of concrete test beams strengthened by U-shaped wrapping methods are significantly improved, reaching 645kN and 720kkN respectively. The fully-wrapped concrete test beam can give full play to the intentional tensile performance of the carbon fiber cloth due to the closed upper part. The maximum shear capacity of the reinforced concrete test beam reaches 875kN, which is an increase of 153.62%. Although the full-wrap adhesive reinforcement can make full use of the strength of the carbon fiber cloth, the construction is relatively difficult. Compared with the U-shaped adhesive, the construction is less difficult, which is conducive to the application in engineering;

(4) The effect of passive reinforcement(carbon fiber reinforcement) is obviously better than that of active reinforcement(wire rope reinforcement), and the improvement of its shear capacity is more powerful, and the maximum can be increased to about 2.5 times. At the same time, the passive reinforcement method is relatively simple and only needs to be equipped with a suitable dipping glue, which is less difficult for construction, lower economic cost, easier to promote, and will be widely used in engineering.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

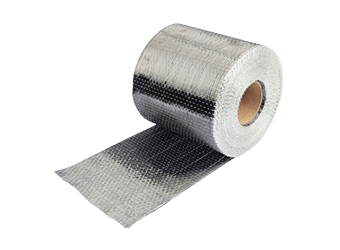

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.