Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

carbon fiber for structural reinforcement

The carbon fiber structural reinforcement method originally originated from the western developed countries. With the continuous development of my country's construction technology in recent years, my country has also actively integrated advanced Western reinforcement technology. At present, the carbon fiber structural reinforcement method is also widely used in many fields in my country. I don’t know if you have thought about such a question. Why is this reinforcement method approved by many contractors and becomes the preferred reinforcement method for reinforcement construction? Today let Horse construction answer for everyone.

First look at the unparalleled advantages of carbon fiber structural reinforcement

1. High strength, high efficiency and high elastic modulus. Its tensile strength is 8 to 10 times higher than that of ordinary steel. It is integrated with the bonding resin and the structure to form an integrated body. It can work reliably with reinforced concrete, has excellent reinforcement effect, and has a wide range of applications and easy quality assurance. .

Second, the construction is convenient, the work efficiency is high, there is no wet operation, no on-site fixing facilities are needed, and it can adapt to the reinforcement of various structural shapes without changing the external dimensions of the components. It can be pasted in multiple layers, and can effectively close the cracks of concrete, and the construction takes up less space. The traditional methods of reinforcement and reinforcement, such as the concrete-clad method and the steel-bonded method, require a lot of chiseling, planting reinforcement, welding, and pouring concrete, but carbon fiber cloth construction is not required. Therefore, it has very low requirements for construction space, facilitates operation in narrow spaces, and has little interference with production and use.

3. Excellent corrosion resistance and durability. Carbon fiber can effectively protect the concrete and steel bars of components from corrosion by acids, alkalis, salts, water and other media. The carbon fiber and rubber structure itself and its reinforced components can withstand ultraviolet rays and nuclear radiation for a long time; long-term use at -54 ~ 80 ℃, the strength will not be reduced, and after the surface coating, the durability is more prominent.

4. After the reinforcement and repair, the weight of the original structure is basically not increased, and the original structure can be maintained, the appearance is beautiful, and the size of the original component will not change much. After pasting, the surface can be painted, pasted with decorative materials, and fireproof materials.

The above explains the advantages of carbon fiber structure reinforcement, the following is introduced from the perspective of the constructor:

1. Great social benefits

Compared with other reinforcement construction materials, carbon fiber reinforcement materials are more environmentally friendly construction materials, and relatively little construction waste is generated during the construction process. In addition, the impact on the normal lives of citizens around the reinforced construction buildings is also small. This kind of reinforcement technology is also widely used, and is currently widely used in various municipal reinforcement projects, which can create more social benefits.

2. High economic efficiency

When customers and construction units choose the reinforcement method, they will consider the economic and practicality of the reinforcement method. The market price of carbon fiber reinforcement materials is relatively low, and the construction is convenient. It can also save more construction costs, which is different from other kinds of reinforcement methods. In comparison, this kind of reinforcement method is relatively economical.

3. Wide application prospects

Although carbon fiber reinforcement material is a new type of reinforcement material, in recent years, my country's research on carbon fiber reinforcement material has been continuously increased, the advantages of this material are obvious, the application field is relatively wide, and the future development prospects are relatively good.

4. Long service life

According to research data, the service life of carbon fiber reinforced materials is more than 50 years, which is unmatched by other reinforced materials. Compared with commonly used steel plate materials, steel plates are prone to corrosion, and problems like this are never seen in carbon fiber reinforced materials.

Fifth, the market sales field is wider

When customers choose reinforcement materials, they first focus on price, followed by reinforcement quality, and the difficulty of reinforcement construction. Compared with the various reinforcement materials sold in the building materials market, only the carbon fiber reinforcement materials can meet all the requirements of the above three customers. Especially for customers who want to save reinforcement costs, carbon fiber reinforcement materials are the best choice.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

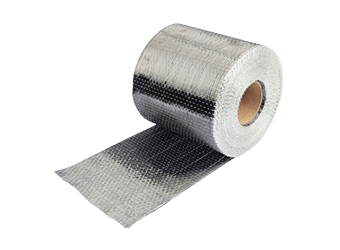

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.