Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Carbon fiber is still a relatively new material in the field of structural reinforcement and repair. Therefore, there will always be various problems during construction. Now Horse Construction has summarized these issues and given some suggestions, hope it can help you.

Carbon fiber is still a relatively new material in the field of structural reinforcement and repair. Therefore, there will always be various problems during construction. Now Horse Construction has summarized these issues and given some suggestions, hope it can help you

About the construction environment?

1) Temperature: The temperature of the construction environment shall comply with the specifications of the structural adhesive product specification. If not specified, it shall not be lower than 15 ° C.

2) Operation site: no dust, and free from sunlight, rain and chemical pollution

Have you measured the moisture content of the concrete before brushing?

The moisture content of the concrete where the fiber material is pasted should not be greater than 4%, and should not be greater than 6%. Concrete whose moisture content exceeds the limit should be artificially dried or replaced with a special structural adhesive for high-humidity surfaces.

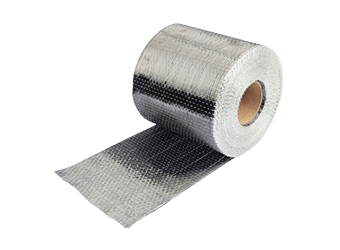

What are the key points of carbon fiber fabric storage?

dry, ventilated, moisture-proof, rain-proof, sun-proof, and away from power!

Do you wait for the primer to dry when applying the structural adhesive with primer?

Finger dry is an important node of the construction ring. At this moment, the adhesive has been properly gelled and has lost its fluidity, but the surface of the adhesive film has not been passivated. This is the best time to attach carbon fiber cloth.

The bonding material is a primer-free adhesive. Have you eliminated it directly?

The product name, model and product instruction manual should be checked and confirmed by the supervision unit before the primer is allowed to be removed.

Why is the viscosity of the A component of the dipping rubber too high?

When the temperature drops sharply during construction, the viscosity of the component A of the dipping rubber tends to be too high. Pre-heating measures (electric furnace, water bath) can be taken before use.

Do you know when every layer of time is pasted when multi-layer carbon cloth is pasted?

When the glue impregnated on the surface of the carbon cloth reaches the dry state, immediately stick the next layer. If the delay time exceeds 1h, wait for 12h before repeating the paste.

Why does carbon cloth generally not exceed 4 layers?

After a large number of experiments, it has been proved that the number of layers of carbon cloth can not easily exceed 4, and the number of layers is too large.

Did you apply glue after the last layer of carbon cloth was pasted?

After the last layer of fiber fabric is pasted, it should be evenly coated with a special structural glue for dipping and bonding.

Which points are likely to cause the fiber material to be weakly bonded?

1) The impregnating rubber was not applied within the applicable period.

2) Too little amount of dipping rubber.

3) The amount of glue used is different for different concrete bases. New base glue is more likely to be weak, while old base glue is less likely to be weak.

Carbon fiber plate glued "medium thick edge thin" do you know?

When applying, the adhesive layer should be thick in the middle of the board and thin on both sides, with an average thickness of 1.5mm ~ 2mm.

What should I do if a large empty drum area is found during quality inspection after carbon fiber is pasted?

When inspecting the quality of pasting, the area of a single hollow drum ≥10000mm2 should be cut off and repaired, and the same amount of fiber composite material should be re-adhered. When pasting, the overlap length of each end in the direction of force (in the direction of grain) should not be less than 200mm. If the number of pasting layers exceeds 3 layers, the overlap length should not be less than 300mm; the overlap length of each side in the unstressed direction (crosswise direction) can be taken as 100mm.

Do you have a way to ensure that no cracks appear on the outer mortar cover?

1) Structural glue should be completely solidified and dried before construction.

2) Wet the carbon fiber cloth with an appropriate amount of water before construction, and the mortar protective layer after painting should be watered for curing.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.