Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

carbon fiber reinforcement is a brand-new reinforcement technology that effectively solves the defects in reinforcement methods

Carbon fiber reinforcement technology is a new type of reinforcement technology that has emerged in recent years and is the fastest growing. Carbon fiber reinforcement technology began in developed countries such as Japan and the United States in the 1980s. China started late, and started using this technology around 1998.

There are many hidden dangers in current construction projects. Mainly due to the low design load standard at that time, after the use function changed, it could not meet the current needs of people. These construction projects urgently need repair and reinforcement. The reinforcement method is mainly selected according to the specific conditions of the project, such as the large-section method, the outer steel reinforcement method, and the carbon fiber reinforcement method. Among them, carbon fiber reinforcement is a brand-new reinforcement technology that effectively solves the defects in reinforcement methods such as large concrete sections.

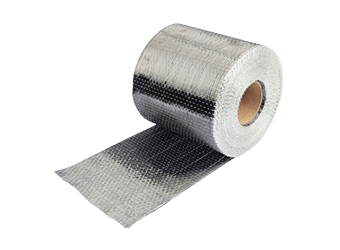

Carbon Fiber Reinforced Polymer

Carbon fiber density is less than that of steel, but its strength is greater than steel. In use, the maximum tensile strength of carbon fiber can reach 9 times that of steel. This high-strength, high-elasticity and corrosion-resistant feature is well applied in construction and also has flexibility. Carbon fiber can be processed, even after the surface is strengthened, there is an unbalanced area, it can be adhered as a whole. In addition to these advantages, carbon fiber is also a lighter-weight material. After pasting, the weight per square meter is less than 1kg and the thickness is less than 1mm, and the original structure size and weight will not be increased after reinforcement.

Compared with traditional concrete reinforcement, carbon fiber construction is simple, reducing the space utilization rate, without the need to reinforce the on-site fixed facilities, and the construction quality is higher. During construction, the structure size and thickness will not be increased, and the durability is good. The application of this construction reinforcement method can increase the service life of the building, so this material is used in many industries.

Structurally strengthened carbon fiber should be continuous fiber with high strength or high elasticity. It is mainly attached to the concrete components of bridges and the areas that need to be reinforced. After curing with resin, it forms a new force composite with the original and jointly bears the force. After being reinforced with carbon fiber, it can be suitable for a variety of structural types, and can be repaired at multiple locations, such as beams, slabs, columns, piers, cylinders and other structures. It is required that the strength of the base concrete is not lower than C15.

Carbon Fiber Adhesive

The bonding material plays a key role in carbon fiber sheet strengthening.

It not only ensures that the carbon fiber filaments work together, but also ensures that the carbon fiber sheet and the reinforced structure work together, so as to achieve the purpose of reinforcement. The bonding material generally uses epoxy resin. Therefore, the performance of epoxy resin is one of the important indicators.

The bonding material should have sufficient rigidity and strength to ensure the transmission of shear force between the carbon fiber sheet and the concrete. At the same time, it should have sufficient toughness, and it will not be damaged by brittle bonding due to concrete cracking. It should also be adapted to the conditions of the construction site, that is, it can be cured under general conditions. It has suitable fluidity and viscosity, and the curing shrinkage rate is small.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.