Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

cfrp sheets, beam strengthening, shear strengthening

CFRP Sheets reinforcement is widely used in building beams, slabs, columns and bridge structures. The force of diagonally pasting CFRP Sheets is more reasonable than that of forward pasting. This article focuses on the construction technology and quality control of reinforced concrete beam diagonally pasted CFRP Sheets for shear reinforcement.

1 Construction technology and safety measures of CFRP sheet reinforcement

The bonding strength is determined by the interface bonding force between the adhesive and the adherend, the internal stress of the adhesive layer and the strength of the adhesive layer. Therefore, it is very necessary to implement the bonding process correctly. In order to ensure the bonding quality, the following conditions must be met:

1.1 Appropriate adhesive

1.2 Good wettability on the surface of the adhered material

1.3 Necessary anchoring measures

1.4 Reasonable bonding process

2 Reasonable choice of adhesive

Adhesives must have three conditions to bond the two adherends firmly:

2.1 The adhesive should be easy to wet

2.2 The adhesive should be easy to flow;

2.3 It can be cured by chemical or physical action to produce sufficient binding force. Specifically, the choice of adhesive should be considered from the following four aspects:

(1) Adhesive material;

(2) Conditions of use:

(3) Process method;

(4) Price

The structural adhesive must have high strength, strong adhesion, aging resistance, high elastic modulus, small thermal expansion coefficient, and a certain degree of elasticity. Except for high-strength concrete, the strength and bond strength of the glue itself are always greater than the strength of the bonded concrete. In addition, the glue used to strengthen the concrete structure should also have good creep resistance, fatigue resistance, durability and atmospheric aging resistance, so as to ensure that when the structural members are damaged, their bonding will not be damaged. Furthermore, components that withstand dynamic loads or high seismic requirements should also have good impact resistance and durable strength.

When choosing CFRP reinforcement for concrete structures, it is best to provide supporting adhesives from carbon fiber manufacturers. If carbon fiber is used and the manufacturer does not provide adhesives, rigid rubbers with higher elastic modulus and lower linear expansion coefficient should be used. Generally, epoxy resin is used as the main agent, and further measures are taken to reduce deformation in the formulation and process to meet the needs of concrete structure reinforcement.

3 Surface treatment of adherend

The surface treatment of CFRP reinforced concrete is the surface treatment of structural members. The purpose of surface treatment is to remove the loose layer and contaminants that hinder the bonding surface: increase the surface area of the adherend and increase the bonding force; change the chemical structure of the surface of the adherend, and increase the surface energy to facilitate the infiltration of the adhesive.

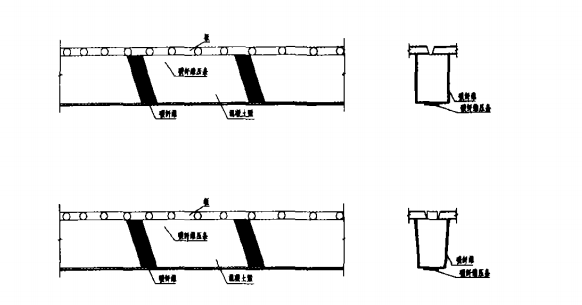

4 Anchorage suggestions and construction methods for obliquely pasted CFRP sheet

Anchor suggestion for diagonally pasting CFRP

Since CFRP cannot be pasted obliquely to form a single full-section pasted anchorage, two carbon fibers must be pasted at the symmetrical positions on both sides of the reinforcing member.

Construction methods under different circumstances

In actual engineering, the difference in the cross-sectional form of the beam and the form of the plate selected will change the construction method.

Other measures to ensure the effectiveness of reinforcement

In order to reduce the stress and strain hysteresis of CFRP, the components should be unloaded appropriately before sticking CFRP. There are two types of unloading: direct unloading and indirect unloading. Direct unloading is the direct removal of all or part of the unloadable load acting on the original structure. Direct unloading is intuitive and accurate, but the unloadable load is limited, generally only part of the live load. Indirect unloading is the use of certain equipment to add a reverse force to the original structure to offset or reduce the original effect. The indirect unloading value is relatively large, and even the effect can be negative. There are two types of unloading: wedge-lift unloading and jack-up unloading. The former is controlled by deformation and has a larger error; the latter is controlled by force, which is more accurate. Generally speaking, multi-point uniform jacking should be used for members that bear uniformly distributed loads.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Good impregnation carbon fiber adhesive for applying carbon fiber reinforced polymer(CFRP) wrap for structural strengthening

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.