Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

The factors affecting the performance of the completed repair and protection system must be evaluated. The following are some of the more common factors that must be considered in maintenance and protection projects.

The factors affecting the performance of the completed repair and protection system must be evaluated. The following are some of the more common factors that must be considered in maintenance and protection projects.

a) Inferior concrete or insufficient coverage: Degraded concrete has too many internal cracks, internal voids, lack of consolidation, insufficient air gap system entrainment or other substandard conditions, which may lead to corrosion of steel bars and structural degradation.

During the repair process, the lack of concrete was removed. Properly selected protection systems can improve the long-term durability of poor-quality concrete, enhance the performance of high-quality concrete, and extend the life of any repair.

b) Misplaced steel bars: during repair / installation of the protection system, the misplaced steel ends, corners, hooks and steel bars on the places where there is less concrete coverage will provide extra material or coating. Cathodic protection in repair materials, chloride extraction and corrosion inhibitor additives can also be used to prevent or delay future corrosion.

C) Permeability: hydrostatic pressure, moisture vapor pressure, capillary action and rain may cause water to penetrate into the concrete. Water movement inside the concrete may be caused by cracks, porous concrete, lack of entrained air, structural defects, or incorrect joint design or function.

This moisture can cause corrosion of the steel bars, freeze-thaw damage, penetration into the structure and possible structural damage. When designing the protection system, try to reduce the flow of water and directly control the rust of steel.

d) Carbonation: Carbonation reduces the protective alkalinity of concrete due to absorption of carbon dioxide and moisture. In ordinary concrete, the reinforcement is protected by the natural high alkalinity (pH above 12) of the concrete surrounding the reinforcement.

A protective oxide layer is formed around the reinforced steel to help prevent the reinforced steel from corroding at high alkalinity. The absorption of carbon dioxide and water in concrete reduces the useful alkalinity of concrete through a process called carbonization.

When the pH value is lower than 10, the chance of corrosion is greatly increased. Reinforcing bars close to the outer surface are affected by carbonization and therefore cannot prevent corrosion.

In the case of insufficient concrete cover, the barrier coating can provide protection for future carbonization. Otherwise, a cathodic protection system or re-alkalinized concrete can be used to protect the steel from future corrosion.

e) Anode ring (halo effect): This effect occurs when existing reinforcement extends from the parent concrete into the repair mortar or new concrete. This results in an increase in the potential difference at the bond line between the new concrete and the mother concrete.

The anode ring or halo effect is due to the damage caused by the accelerated corrosion of the reinforcing steel in the base metal concrete, just beyond the edge of the repair. Corrosion occurs at the anode, usually in the parent concrete, because electrons are absorbed into the cathode portion of the reinforcement material in the uncontaminated repair material.

The accumulation of rust will cause a great internal pressure on the surface of the steel bar, which will cause the concrete to peel off. The presence of chloride accelerates the process.

Barrier coatings on reinforcing steel include epoxy resins, latex slurries or zinc-rich coatings, which can partially help control corrosion activity. But there are problems with field application. Cathodic protection, chloride extraction and electroplating anodes can also be used to protect steel from corrosion. However, the economics of these solutions should be considered.

F) Cracks: Crack repair is usually the first step in any repair or protection work. The water present in the cracks can cause corrosion and freeze-thaw problems in cold climates. Before repair work, the cause of the crack must be investigated.

Structural cracks must be repaired in such a way that they can transmit loads through the cracks. Epoxy resin injection is used to ensure the sealing of cracks. Active cracks, especially those caused by thermal changes in external exposure, must be repaired for future use.

Active thermal cracks can be repaired by providing appropriately designed expansion joints. The use of caulking, chemical grouting, elastomer coatings and high-elongation epoxy resin can repair moving cracks. Repairing exposed active cracks can be difficult.

Most materials used for crack repair are temperature sensitive and therefore cannot be installed below 4 ° C. It is also desirable to repair when the crack is close to its maximum width, because most flexible materials used to repair active cracks perform better in compression than in stretching.

G) Chloride / chemical attack: The penetration of chemical or salt solutions in concrete can cause corrosion of embedded steel. Chemical attack by acids, alkalis and sulfates may also have an adverse effect on concrete. Isolation protection systems are often used to minimize the intrusion of chemicals into concrete.

H) Surface erosion: The surface erosion of concrete is the main problem of dams, spillways and other waterfront structures as well as bridge decks, ramps, parking decks, industrial floors and other traffic carrying structures.

To a lesser extent, it can also be a problem for buildings exposed to acid rain and severe weather conditions. Concrete coatings, surface hardeners, sealants or other treatment methods are often used to increase the corrosion resistance of the surface.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

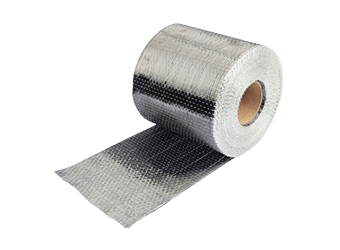

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package for anchoring