Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Why Do Test Before Structural Reinforcement? Keypoint of Test?

The reason why it is necessary to conduct inspections before structural reinforcement is to determine the current situation of the structure, evaluate structural problems and damage conditions of the structure, and select an appropriate reinforcement scheme.

Structural reinforcement is aimed at improving the strength and stability of structures and reducing the destruction and damage of structures under natural disasters such as earthquakes, wind disasters, or other external forces. However, different structures have different defects and damages, requiring different reinforcement schemes. Without testing and evaluation, it is impossible to determine the specific situation of the structure, and it is difficult to choose an appropriate reinforcement scheme, which may lead to poor reinforcement effects and even exacerbate the damage to the structure.

Through testing and evaluation, it is possible to understand the strength, stability, defects, and damage of the structure in order to select an appropriate reinforcement scheme. Detection and evaluation can be carried out through various methods, such as structural calculations, simulation analysis, on-site testing, and so on. Through these methods, it is possible to evaluate the strength, stiffness, deformation, cracks, and other conditions of the structure, thereby determining the reinforcement plan, and formulating a detailed reinforcement plan to ensure the effectiveness and safety of the reinforcement project.

Therefore, for buildings requiring structural reinforcement, adequate testing and evaluation must be conducted to select appropriate reinforcement schemes and ensure the effectiveness and safety of the reinforcement project.

The following are some key points for the identification and testing of building structures:

Test scope: The identification test shall cover all structural parts of the building, including foundations, walls, beams, columns, floors, and other parts.

Testing methods: Identification testing can adopt various methods, such as on-site testing, non-destructive testing, structural calculations, and simulation analysis.

Testing tools: Professional testing tools and equipment, such as structural calculation software, crack meters, and elastic modulus meters, are required for identification testing.

Testing standards: Identification testing should follow relevant testing standards, such as national building standards, industry standards, technical specifications, etc.

Testing personnel: The identification and testing should be carried out by professionals with relevant qualifications and experience, such as registered structural engineers, architectural engineers, building materials experts, etc.

Test report: The identification test requires the preparation of a detailed test report, including the evaluation results of the building structure, descriptions of structural defects and damages, and recommendations for reinforcement plans.

Identification cycle: The structural identification and testing of buildings should be conducted regularly to ensure that structural problems are promptly identified and addressed to avoid accidents.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

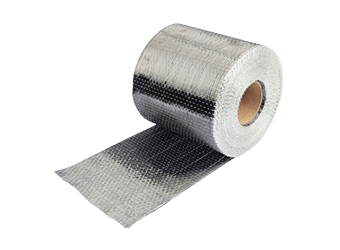

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.