Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Shear Wall Structure Reinforcement Method

The shear wall structure uses reinforced concrete wall panels to replace the beams and columns in the frame structure, which can bear the internal force caused by various loads and can effectively control the horizontal force of the structure. This kind of structure that uses reinforced concrete wall panels to withstand vertical and horizontal forces is called shear wall structure.

Shear wall structures are increasingly used in high-rise buildings because of their good integrity and excellent seismic resistance. However, such as insufficient concrete strength, cracks, design defects, etc., will lead to insufficient bearing capacity and strength of the shear wall, thus affecting the structural integrity and safety of the shear wall.

So, how should the shear wall structure be reinforced when the bearing capacity does not meet the specification requirements or actual needs? The following are some commonly used reinforcement methods.

01 Enlarged section reinforcement method

When the bearing capacity of the wall does not meet the requirements of the specification, or when the size, reinforcement and axial compression ratio of the wall do not meet the requirements of the specification, or when the concrete strength of the wall is low or the construction quality has serious defects. Both sides of the original wall, single side or partial addition of reinforced concrete post-casting layer can be used for reinforcement. The thickness of the newly added concrete layer is determined by calculation, generally it should be ≥60mm. The strength grade of the newly added concrete should be one grade higher than that of the original concrete, and should not be lower than the C25 grade. The specifications of the new reinforcement mesh for the wall are determined by calculation. Generally speaking, it should be: vertical reinforcement ≥ Φ10-12, spacing 150-200, horizontal reinforcement ≥ Φ8-10, spacing 150-200, vertical reinforcement inside, horizontal reinforcement outside. The newly added steel mesh should have a reliable connection with the original wall. Generally, tie bars or planted bars can be used to connect. The specifications of the tie bars and planting bars are generally Φ6-8, the spacing of the tie bars is 900, and the spacing of the planting bars is 600, and the plum blossom arrangement is generally adopted.

02 Bonding steel plate reinforcement method

When the wall is only due to insufficient transverse reinforcement, it can be reinforced by the method of pasting steel plates, that is, setting horizontal transverse flat steel on the surface of the wall. When the wall reinforcement is insufficient, the structure of pasting steel plates should not be implemented and should not be used. The specification and distribution of flat steel are determined by calculation, generally take (80-120)*(3-4)@300-500, and the flat steel should be additionally anchored by chemical anchor bolts. The ends of the flat steel should be reliably anchored. Generally, an anchoring angle steel can be set at the intersection of the vertical and horizontal walls, and the flat steel is welded to it. The welding position should be welded first and then poured with structural glue.

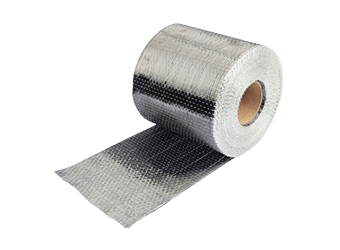

03 Carbon fiber mesh reinforcement method

When the wall is insufficiently resistant to earthquakes and cracks, the wall is eccentrically compressed or the strength of the wall concrete is insufficient, the carbon fiber grid reinforcement system can be used for reinforcement. The carbon fiber grid reinforcement system is through the joint action of carbon fiber material and special wet shotcrete mortar, fully integrating the advantages of the material, realizing the bonding of carbon fiber grid and concrete components, and achieving the effect of joint stress. The general carbon fiber and mortar have a very small grip. By coating a layer of special interface treatment agent on the surface of the carbon fiber, the grip between the mortar and the carbon fiber is guaranteed. The thickness of mortar and the number of layers of carbon fiber mesh can be determined according to the actual situation on site. Generally, the thickness of one layer of carbon fiber mesh is 15mm. And the carbon fiber grid has excellent fire resistance, and the 1cm mortar protective layer can reach the fire resistance standard of 60 minutes.

In the shear wall structure and frame shear structure, the shear wall is the main force-bearing component and plays a very important role in the structure. Therefore, it is necessary to reinforce the disease in time to prevent the disease from expanding further.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package

Modified epoxy resin structural perfusion adhesive, specifically for supporting adhesive bonded steel reinforcement