Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

As a manufacturer of structural reinforcement materials, how to prevent hollowing out of carbon fiber reinforcement from the source?

How to solve the hollowing out of carbon fiber reinforcement from the source? In fact, it is very simple, it is to choose the right structural reinforcement material.

As a leader in structural reinforcement materials, Shanghai Horse has established its first carbon cloth production line in 2008, and carbon fiber cloth has become the main product of Horse reinforcement materials. In response to the hollow carbon cloth problem that has plagued the market for many years, Horse has optimized the raw materials, production equipment, process technology, construction process, etc., to fundamentally eliminate the occurrence of hollow hollows.

1 Raw materials - Imported aviation grade 12k small tow carbon wire

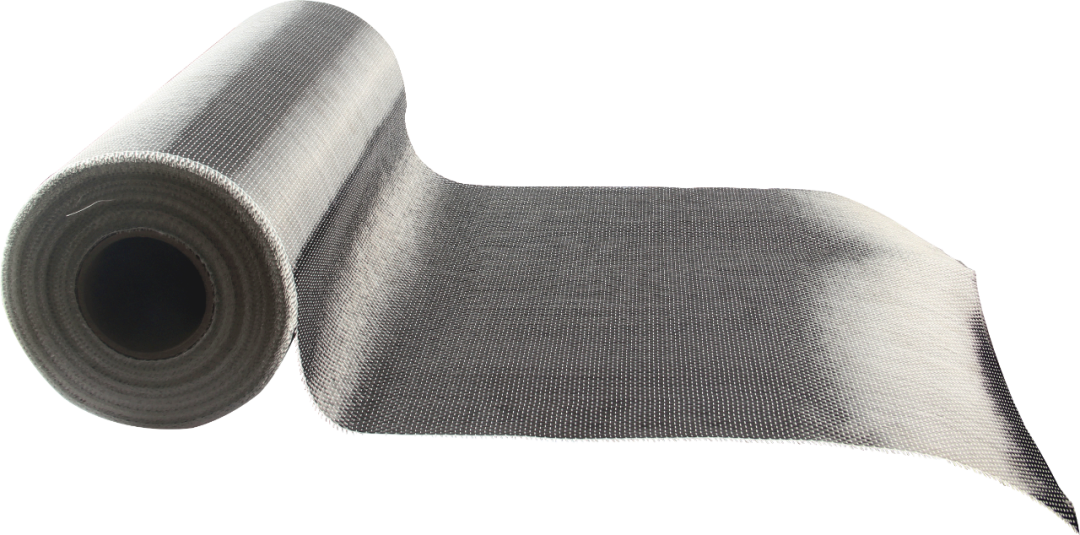

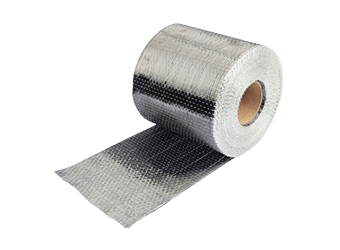

The first is to check from the source. Horse uses imported aviation-grade 12k small tow carbon filaments with a monofilament strength of 5,400 MPa. The 12k small tow makes the glue better infiltration and less discrete. The carbon cloth woven with such carbon filaments is more straight and soft, and has better wrapping properties for the components.

However, the carbon cloth woven with inferior carbon filaments not only has no guaranteed strength, but is also very stiff, and cannot fit the components during construction.

2 Production equipment - DORNIER weaving equipment

Because the imported carbon cloth weaving machine adopts a full computer system to precisely control the warp and weft tension, and the point-to-point positive weft insertion makes the carbon fiber tight and the tension is uniformly distributed. Therefore, the strength of each carbon filament can be exerted, and the woven carbon cloth is more uniform and straight.

However, the domestic traditional looms are outdated and rely on the machine to control the warp and weft tension mechanically, resulting in tight carbon filaments in some places, loose carbon filaments in some places, uneven tension distribution, and large deformation and damage to the carbon cloth. Not only the strength is damaged, but the hollowing phenomenon is easy to appear in practical applications.

3 Process technology - Independent research and development of constant tension system

Horse independently developed a set of creel system. Through the constant tension setting of the creel system, the tension control accuracy of the conveyed carbon filaments can reach 50CN, ensuring that the tension of each bundle of carbon filaments is constant during the weaving process.

Because the tension of the carbon filaments is constant and equal, the woven carbon cloth is even and straight, and there will be no wrinkles during construction and pasting, and it is easy to scrape off, further eliminating the hidden danger of hollowing.

4 7 self-checks to ensure stable quality

Before the products are shipped, Horse will also conduct 4-layer self-inspection and 3-layer re-inspection on the products, and control the product quality layer by layer to ensure that there will be no product quality problems in the products out of the warehouse.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.