Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Concrete Bridge Design Method---Prestressed Carbon Strip

Concrete Bridge Design Method---Prestressed Carbon Strip(1)

4 Box girder reinforcement design

The box section is a closed thin-wall section with the following characteristics:

(1) The box girder has a large top and bottom strip area, which can effectively bear the positive and negative bending moments caused by dead and live loads, and is beneficial to the reinforcement of the beam section;

(2) The box girder has large torsional rigidity, and under the action of eccentric load, the force distribution in the girder is relatively uniform;

(3) For cantilever construction bridges, due to the good integrity of the box girder, it has good static and dynamic stability.

Therefore, box girder is generally used for girder bridges with a span greater than 40m. This article mainly focuses on the reinforcement of the uniform cross-section box girder with the prestressed carbon fiber strip.

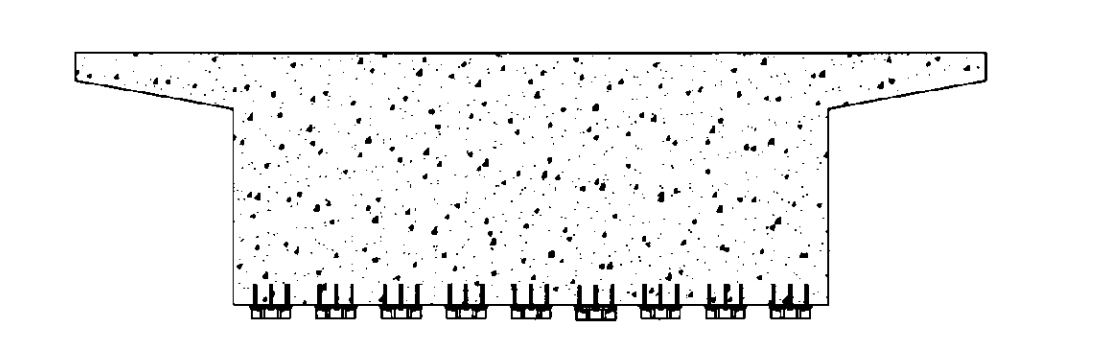

(1) Cross-bridge design

The thickness of the bottom strip of the box girder section is generally greater than 20cm. When the box girder is designed in the transverse direction, a 10cm wide carbon fiber strip can be used for reinforcement. The number of anchors should be arranged according to the width of the bottom of the box girder. The anchor should be drilled and planted at the bottom of the box girder. Try to locate the anchor on the variable thickness section of the bottom. Avoid touching the corrugated pipe during the drilling process. The ideal horizontal bridge layout is shown in the figure below.

Box girder cross-bridge design--prestressed carbon strip

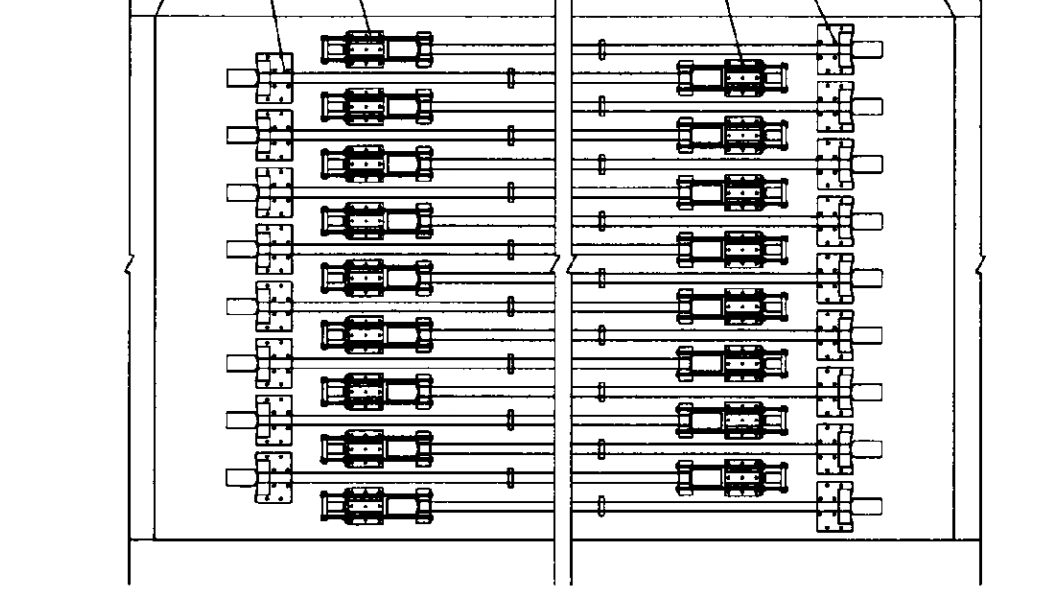

(2) Longitudinal bridge design

When designing the longitudinal bridge direction of the combined small box girder, the tensile end and the anchoring end should be as close as possible to the position of the support, and the anchoring device should be positioned as far as possible in the variable thickness section of the bottom strip. But at the same time, the construction space needs should be considered, and it should not be too close to the support. The anchoring system adopts a staggered arrangement, and the tension end should be spaced a certain distance. The ideal longitudinal bridge layout is shown in the figure.

Longitudinal Bridge Design of Box Girder--Prestressed Carbon strip

As shown in the figure above, a 1.4mm thick, 10cm wide, and L+1m carbon fiber strip is used in the span of the bridge, considering a working length of 1m (L is the distance between the tension end and the anchor end). A number of carbon fiber strips are arranged longitudinally along the bottom strip of the box beam. Anchor ends and tension ends should be arranged in a staggered manner. During the tensioning process, the transverse bridge direction is stretched symmetrically from the middle to the two sides in sequence, the anchoring end is 1.5m away from the centerline of the support, and the tensioning end is 2.5m away from the centerline of the support. .

5 Reinforcement design of multi-span continuous beam bridge

The above subsections are mainly for the reinforcement design of concrete simply supported beams. For the reinforcement design of multi-span continuous beam bridges, it is recommended to adopt a single-span layout through analysis and research instead of using a carbon fiber board to span two or even three-span layouts. The main reason is that, on the one hand, the greater the number of spans, the greater the elongation of the tensioned carbon fiber sheet, the longer the tensioning screw, and the more times the jack will collapse during the tensioning construction, and the construction process is very cumbersome. On the other hand, when the tensile force acts on the pier top section, tensile stress will be generated at the top of the pier top section, which is unfavorable for the section force.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

Prestressed carbon fiber reinforced polymer(CFRP) strip for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.

Prestressed carbon fiber reinforced polymer(CFRP) laminate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.