Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

The Design Principles Of Carbon Fiber Structural Strengthening?

As a new technology, carbon fiber strengthening and repaired structures has its incomparable advantages, but also has its certain scope and conditions of application. It is often unsafe, uneconomical and unreasonable to use this technology blindly beyond its scope.

First of all, the minimum cross-sectional size of the reinforced structural member must meet the requirements of the relevant specifications.

Secondly, the compression zone height, reinforcement ratio, area distribution ratio, volume distribution ratio, etc. of the reinforced component still have to meet the requirements of the existing specifications.

Finally, it is required that the final failure form of the original structure should not be changed after strengthening reinforcement.

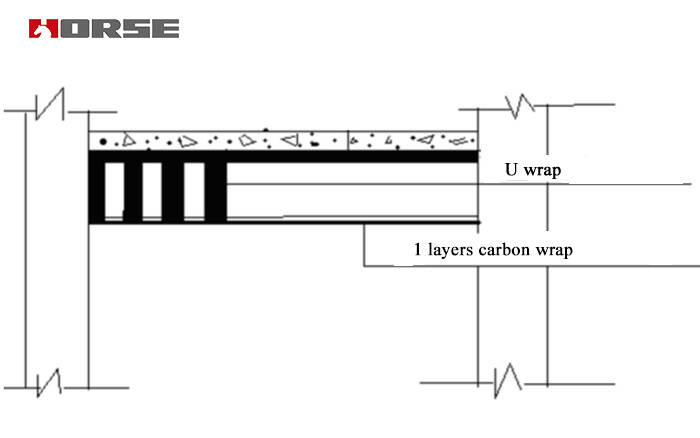

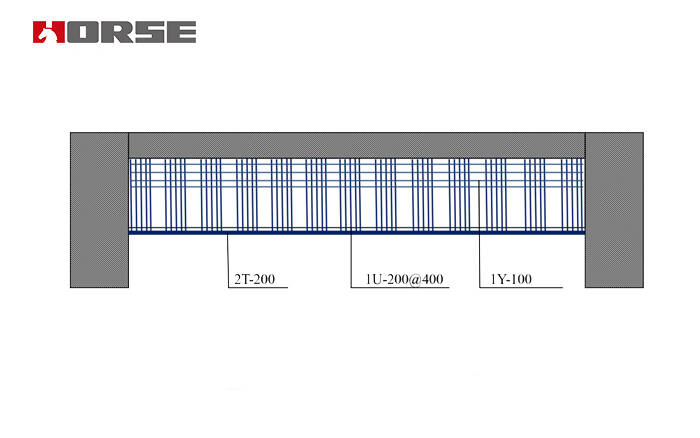

The application of carbon fiber wrap has the problem of efficiency. With the same amount of carbon fiber wrap, the strip strengthening effect is better than the whole. The flexural bearing capacity of the component increases with the increase of the amount of carbon fiber wrap. When the number of layers of carbon fiber wrap used is small, the increase is relatively large. As the number of layers of carbon fiber wrap increases, the increase will decrease accordingly. When the amount of carbon fiber wrap is too much, the damage of the component will change from the damage caused by the breaking of the carbon fiber wrap to the crushing damage of the concrete, and the ductility of the component will be reduced.

Evaluation of the applicable scope of carbon fiber structural strengthening

(1) From the perspective of force performance. Carbon fiber has high tensile strength and fatigue properties, and is mainly suitable for the reinforcement of the tensile area of spit members, especially for the seismic reinforcement of large and medium-sized structures such as bridge beams that are subjected to dynamic loads.

(2) From the perspective of material characteristics. Carbon fiber is a flexible coiled material, which can be processed into U-shape or round shape according to construction needs, and can be used for compression and shear reinforcement of structural beams and columns. Prevent and repair temperature cracks in the wall, and improve the seismic resistance of the brick structure.

(3) From the perspective of practical application. The carbon fiber reinforced concrete technology avoids the disadvantages of other reinforcement methods such as increasing the structural size, reducing the space used in the building, increasing its own weight, long construction period, and poor corrosion resistance. It has been widely used in the reinforcement of bridges, roads, underground structures, towering high-rise structures, industrial plants and other building structures.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

Prestressed carbon fiber reinforced polymer(CFRP) plate for slab, beam strengthening to increase stiffness, reduce distortion and deflection of members, reduce the cracks, avoid and stop cracking.