Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

The Basic Principles Of Concrete Structure Repair And Reinforcement

The repair and reinforcement design of concrete structures is the most important link for the implementation of repair and reinforcement of concrete structures to achieve expectations. The basic principles that should be adhered to in the repair and reinforcement design are as follows:

1: The repair and reinforcement design of concrete structures should be undertaken by experienced professionals

Whether the concrete structure needs to be repaired and strengthened, the reliability of the structure should be appraised. Experts make appraisals based on relevant codes, regulations, and standards, and appraisal opinions can be used as one of the basis for the reinforcement design of concrete structures. Because the uncertain factors faced by concrete structure repair and reinforcement design are far more and more complex than new construction projects, and the owner's requirements must be considered, therefore, the personnel responsible for the repair and reinforcement design have strong structural theory and clear structural concepts. It should also have a relatively rich engineering experience to be able to analyze the problem comprehensively and systematically. Propose a more reasonable reinforcement design plan for the repair structure to achieve the purpose of repair and reinforcement. Not ordinary structural engineers can do a good job of reinforcement design. Engineers who do a good job in new building design can only do a good job of reinforcement design after certain research and engineering practice.

2. Rehabilitation and reinforcement design should deal with the relationship between components and structure, part and whole, temporary and permanent

When some components do not meet the requirements, they must be reinforced, but the reinforcement of the structural system is often overlooked. The reinforcement designer should consider the safety of the entire structural system. When the reinforcement of individual components does not affect the force performance of the overall structural system, local reinforcement can be carried out. When the structure as a whole does not meet the requirements, the structure should be reinforced as a whole; the requirements for temporary reinforcement can be appropriately reduced.

Rehabilitation and reinforcement of concrete structures should be carried out under conditions that minimize production shutdowns, and do not affect or affect work and life.

3. The implementation of repair and reinforcement must be in a scientific order

Usually should be treated first and then reinforced. For structural damage caused by high temperature, high humidity, freezing and thawing, cold brittleness, corrosion, vibration, temperature stress, shrinkage stress, uneven foundation settlement, etc., effective treatment measures should be taken during reinforcement. Eliminate or limit its harmful effects from the source, and correctly determine the timing of reinforcement treatment so that it will not cause damage to the reinforced structure again.

The repair and reinforcement of concrete structures should generally be unloaded or partially unloaded first, and then reinforced in a certain order after unloading. Generally speaking, it should be reinforced first and then demolished. Reinforce first and then open holes; first foundation and then columns, beams and slabs; first important components, then secondary components, and finally protection and protection.

4. Reinforcement design should also pay attention to review the seismic capacity of the concrete structure, and do a good job in seismic reinforcement design

In addition to meeting the requirements for bearing capacity, the reinforcement of structures or members in the earthquake zone should also review its seismic performance. After the structure is strengthened, there should be no new weak spots due to local strengthening or sudden changes in stiffness. At the same time, the influence of the increase or change of the seismic effect caused by the increase or change of the structural stiffness should also be considered.

In the seismic reinforcement design, the following issues should also be paid attention to: the rigidity and strength of the structure should be evenly distributed to avoid the appearance of new weak layers. The vertical components should be continuous to ensure clear, simple and direct force transmission paths. Reinforcing components or strengthening the original components should consider the possibility of reducing the torsion effect of the entire structure. Strengthen the anti-seismic structure of weak parts. It is necessary to make the stress state of the structure more reasonable, prevent brittle failure of the components, and eliminate the unfavorable stress conditions such as strong beams and weak columns and weak nodes of strong members that are not conducive to earthquake resistance. Consider the impact of the construction site; the reinforced structure should choose a structural system with low seismic response. The original unreasonable structure system and the way of force transmission should be improved as far as possible.

5. Use mature methods and technologies for structural repair and reinforcement.

When designing concrete structure reconstruction or restoration and reinforcement, attention should be paid to the selection of new materials, new processes, and the application of mature new technologies. It should be noted that technologies and products that have been formally certified must be used. For other new products and technologies, they should be used after careful research and testing to determine their reliability.

6. Eliminate the stress and strain hysteresis of the reinforced structure

In order to adapt to the stress-strain hysteresis of the reinforced structure, and to fully utilize the potential of the added part, the steel used in the reinforced structure should generally be selected from low-strength (I, II grade) steel with a smaller proportional limit deformation. In order to improve the bonding performance of the joint surface of the secondary composite structure, to ensure that the new and the old parts can work together under the force, the cement and concrete used in the reinforcement structure require small shrinkage. Moreover, it is better to have a slight expansion, good adhesion to the original component, and high early strength. For the chemical grouting materials and adhesives used in the reinforcement structure, high bonding strength, good pourability, small shrinkage, aging resistance, non-toxic or low-toxicity are required.

According to the analysis of the stress condition, the newly added part of the reinforced structure cannot fully exert its effectiveness due to the lag of stress and strain. Especially when the strain stress of the structure is high, the compression member and the shear member will often break the original structure and the added part successively. As a result, the structural reinforcement effect is very unsatisfactory or does not work at all. On the contrary, if the load is unloaded during reinforcement, the situation is different, because the stress and strain hysteresis can be reduced or even disappeared. When destroyed, the old and new parts can enter their respective limit states at the same time, and the total bearing capacity of the structure can be significantly improved.

In principle, the calculation of unloading and strengthening bearing capacity is still carried out according to the secondary force. However, when the unloading reaches a certain level, it can be approximately simplified as a calculation based on a combined structure, especially the tension, bending and large eccentric compression members with steel bars as the main load.

Unloading can be direct unloading or indirect unloading. Direct unloading is the unloading load that is directly removed in whole or in part and acts on the original structure. Indirect unloading is to apply reverse force to the original structure to offset or reduce the original effect. Direct unloading is intuitive and accurate, but the unloadable load is limited and generally limited to live loads. The value of indirect unloading is unlimited, and it can even make the action effect appear negative. Indirect unloading includes wedge-lift unloading and jack-up unloading. The former is controlled by deformation and the latter is controlled by stress. The prestressed reinforcement method and unloading are combined into one, which is a method of partially transferring the load on the structure to the newly added structure through prestressing means.

7. The reinforcement design is very different from the structural design of the new building and should be treated differently

In the calculation of reinforcement design, the reduction of floor live load can be considered. For beams of cast-in-situ reinforced concrete slabs, the effective compression flange width of the cast-in-situ slab should be considered in the middle of the span when calculating the bending bearing capacity. For frame beams with double-reinforced beams in the mid-span and beam-end compression zone, the bending moment when calculating the end bearing capacity and cracks should be taken as the column boundary value instead of the column median value. The concrete strength of each component should be converted to the design value according to the actual measured value of the test. After the overall internal force analysis is done with computer software, the component must be partially checked.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

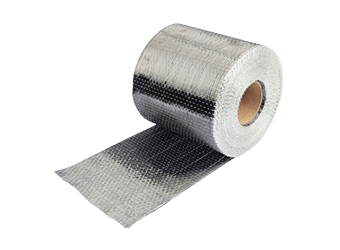

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package