Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Analysis On The Control Design Of Basement Concrete Structure Cracks

With the rapid development of social economy, the construction industry has also ushered in a peak period of development, but it also brought challenges. The number of construction projects has been increasing year by year. In order to better meet the residents’ requirements for the use of buildings and reduce the land area occupied by the buildings, building basements have played an extremely important role. At present, many buildings in my country use basements as parking lots and shopping malls. , Storage warehouses, etc., all of which provide a guarantee for the convenience of residents' travel. However, due to the influence of many factors, the basement concrete structure of high-rise buildings is very prone to cracks. For the entire construction project, the appearance of the basement concrete structure cracks has caused its construction quality and stability to significantly decrease.

1 Material aspect

The main components of basement concrete include sand and gravel, cement, admixtures, etc. The construction materials of the basement concrete structure are cement, sand and gravel aggregates, water, etc., mixed into a cementing material in a certain proportion. In this process, the cement will undergo a significant hydration reaction after encountering water. This reaction will generate a cementitious material that binds some scattered sand and gravel aggregates together. After analyzing this, we found that the occurrence of hydration reaction largely depends on the type of cement. In order to effectively reduce the construction cost of many construction projects, the lack of basement structure is considered important, and cement models with relatively low heat of hydration have been selected. For example, pozzolanic Portland cement has a large proportion of water ash in its composition, large water consumption, high temperature, and high surface humidity, which are prone to cracks. For the above situation, when designing the concrete structure of the building basement, the designer first needs to consider the scientificity and rationality of the design plan, and minimize the occurrence of heat of hydration in construction materials. The designer must strictly control the amount of cement based on the actual situation. The control of coarse aggregate should also be strengthened. Under normal circumstances, the basement concrete structure must meet the relevant acceptance standards while ensuring that the diameter of the coarse aggregate used is <32mm, and the weight of needles and flake particles is <15%. The type and grade of cement should be scientific and reasonable, and the sand and gravel raw materials should also be selected with better quality products, especially the mud content in the sand and gravel raw materials must meet the corresponding standards and specifications. Some water reducing agents, retarders, etc. can be appropriately added for mixing to ensure the overall construction quality of the construction project, while reducing construction costs, preventing the appearance of cracks, and promoting the improvement of the quality of basement construction.

2 Design aspects of basement structure

Improper design of basement concrete structure mainly includes:

The type or grade of concrete is too high, the amount of ash used increases, and the shrinkage speed of the structure surface accelerates; the basement structure design does not have a scientific and reasonable arrangement of post-pouring belts or expansion reinforcement belts;

In order to arrange the position of the steel bar reasonably, the bonding effect between the steel bar and the concrete is not good;

The cross-section of the structural members of the basement suddenly changed, and the stress suddenly concentrated, causing cracks.

In order to ensure the rationality of the design scheme, some structural designs can be improved. For example, keeping the grade of concrete in a moderate state. Appropriately add some micro-expansion agent during concrete mixing. If the basement is relatively long, the involved personnel must pay attention to the reasonable layout and explain it, that is, set aside corresponding positions in the building foundation floor, beams, side walls, etc., as temporary construction gaps. Divide the big one into several small structures, and after the construction contraction ends, restore the small structures into a whole. This method of operation can largely prevent the occurrence of uneven concrete settlement. In addition, it can also effectively avoid the occurrence of cracks caused by shrinkage and other reasons, and effectively ensure the stability and durability of the basement structure of the construction project. The designer should also pay attention to the reasonable arrangement of the steel structure when designing. If the reinforcement ratio is the same, try to choose some thin steel bars for dense distribution. If necessary, some crack-resistant steel bars can be used instead of steel bars. If the span of the basement section is relatively large, for the waist reinforcement of the higher section of the concrete beam, not only should it meet the corresponding specification standards, but also the distance between the steel bars can be appropriately reduced or increased according to the actual situation. Then there is the design of the thickness of the concrete protective layer. If the basement is in an environment with alternating dry and wet conditions or contains harmful media, the surface of the basement concrete structure and components should be plastered or thickened to strengthen the prevention and treatment of cracks.

3 Uneven settlement of foundation

Uneven settlement of the foundation is a common phenomenon in many construction projects, especially in the middle of a building, with a depression in the middle and a bulge around it. In different building sections, the foundations are very likely to be unevenly distributed, leading to increased local loads. When the foundations cannot withstand the pressure, they will sink. If the overall strength of the entire building is low, it will appear as a wall crack. Especially in the area close to the sinking foundation, the cracks are more obvious. It has a greater impact on the stability of the entire building, and even seriously threatens the personal safety and property safety of residents. Therefore, in order to effectively avoid cracks in the basement structure, designers should appropriately reduce the weight of the concrete structure based on the actual situation, and improve the structure and configuration of the concrete, so as to better deal with the settlement of the foundation. During the construction process, the construction personnel should pay special attention to strengthen the control of the uneven settlement of the foundation. Maintain the entire construction process of the basement concrete structure as much as possible, avoid cracks in the concrete structure as much as possible, and ensure the life and property safety of the owner.

4 Specific cases

The Qianjiang Century City residential project in Xiaoshan District, Hangzhou City, Zhejiang Province, has two basements with frame structures. When designing the basement structure, the use permission is 50 years. When all the design standards meet the relevant specifications, the safety level of the basement building structure is level two, and the combustion performance and fire resistance limit of the materials used meet the requirements of the corresponding fire resistance level and fire protection specifications. The concrete strength grade foundation cushion is C20, the basement floor, outer wall, top slab, and inner wall are all C35, and the equipment foundation for subsequent pouring is C25. The basement floor, exterior walls, and pool exterior walls are all grade two, and the top slab is grade one, using waterproof concrete. The impermeability level of the basement of the 2nd underground floor is P8, and the impermeability level of the fire-fighting pool for the outer wall of the 2nd underground floor, the basement of the 1st underground floor, and the outer wall of the first underground floor is P6. The basement floor, external walls, roof, and roof beams are all made of shrinkage-compensating concrete. Finally, the floor has been protected with water, and the remaining parts have been cured with moisture.

5 concluding remarks

In short, the control design of basement concrete structure cracks is of great significance for improving the safety and stability of basement concrete structure. Although some small cracks on the surface of the basement concrete structure will not have a major impact on the bearing capacity and durability of the entire building. However, by strengthening and improving the materials used in the construction of basement concrete structures, structural design schemes, and uneven foundation settlement, the appearance of cracks on the surface of basement concrete structures can be effectively controlled.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

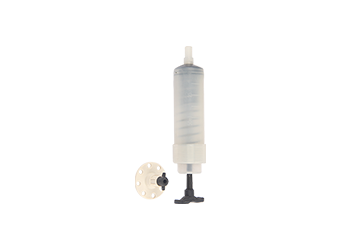

Very strong penetration and low viscosity epoxy crack injection adhesive for repairing concrete crack

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.