Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

How to Bonding Carbon Fiber On Different Components for Structural Strengthening?

When the structure is reinforced, it is advisable to adopt a thin carbon fiber multilayer pasting method. When the carbon fiber cloth is thin and pasted layer by layer, the fibers of each layer can be fully wetted with the bonding glue, so the bonding efficiency is higher.

Although the force characteristics of members under tension, compression, shear and torsion are different, they are all members whose stress in the same direction is basically distributed across the entire section.

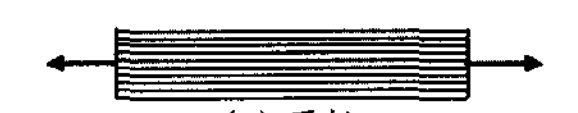

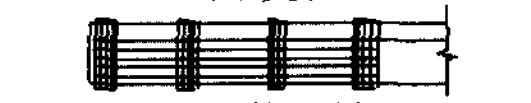

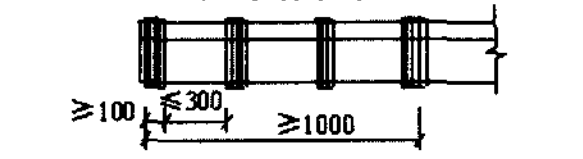

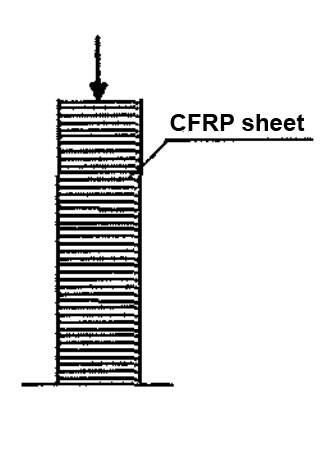

Therefore, it is possible to use all-inclusive paste along the axial direction to strengthen the tension member. Adopt all-around and all-enclosed paste for compression members. The shear and torsion components are pasted on both sides and additional equidistant closed winding hoops are set. For the bending member, the carbon fiber cloth can be used to stick the carbon fiber cloth in the tension zone of the member straight along the axial direction. In order to fully bond and anchor the carbon fiber cloth pasted on the bending member, additional anchoring treatment can be performed at the end of the section of the carbon fiber cloth in the main fiber direction. When the reinforced bending member is a beam, additional equidistant closed winding hoops should be set at both ends of the beam. The carbon fiber cloth pasting method of various components is shown in the figure.

Carbon fiber reinforced tensile member

Carbon fiber reinforced shear and torsion members

Carbon fiber reinforcement for bending members

Carbon fiber reinforcement for compression members

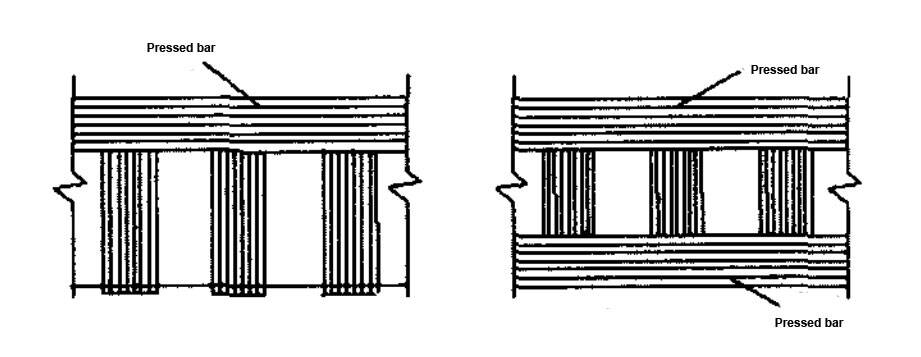

The width of the carbon fiber cloth with the equal-spaced closed winding hoop should be greater than 100mm, and the clear spacing should be less than 300mm. When used for shear and torsion members, it can be set along the reinforcement section, and for beam-type bending members, it can be set separately in the section where both ends are larger than lm.

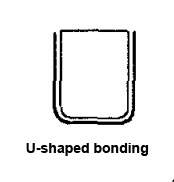

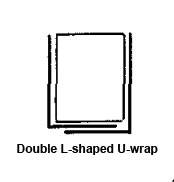

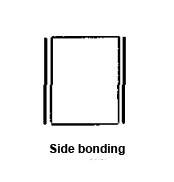

When the two ends of shear, torsion member and beam-type bending member cannot be equipped with closed winding hoops due to conditions, the shear and torsion member can be directly reinforced with U-shaped paste in the reinforcement section. U-shaped hoops can be respectively arranged in the section larger than 1m at both ends of the beam-type bending member. At this time, the U-shaped pasted carbon fiber cloth and the U-shaped hoop fracture end should be closed with longitudinal bead to ensure the reinforcement efficiency of the carbon fiber cloth. as the picture shows.

U-wrap bonding and side boning anding longitudinal pressing strip

Matters needing attention in the application of carbon fiber reinforcement

1) Unloading the reinforcement components according to the design requirements during construction can eliminate or reduce the cracks and deformations that have occurred in the components, improve the utilization efficiency of carbon fiber cloth, and make carbon fiber cloth participate in the work as soon as possible.

2) The carbon fiber cloth of the reinforcing member should not be overlapped along the main fiber direction, especially for the reinforcement of the tension member and the tension area of the bending member. If it is necessary to overlap, its position should avoid the most stressed section of the component, the overlap length should not be less than 100mm, and the overlap end should be flat and free of warpage. When multiple or multiple layers of carbon fiber cloth are used for reinforcement, the overlapping positions between the layers of carbon fiber cloth should be staggered with each other, and the clear distance between the interface positions of each layer should be greater than 200mm.

3) In order to ensure the effective bonding and anchoring between the flexural member and the reinforced carbon fiber cloth and prevent the reinforcement failure caused by peeling damage, the end of the carbon fiber cloth fracture of the reinforced flexural member must be anchored, and additional anchoring measures should be taken if necessary. Generally, a full-length carbon fiber cloth bead is used. The bead should be pasted perpendicular to the main fiber direction of the reinforced carbon fiber cloth, and its width should not be less than 500mm.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

High strength carbon fiber reinforced polymer (CFRP) strip / laminate / plate for structural strengthening and concrete repair

High strength, unidirectional carbon fiber fabric pre-saturated to form a carbon fiber reinforced polymer (CFRP) fabric used to strengthen structural concrete elements.

High strength, unidirectional carbon fiber sheet pre-saturated to form a carbon fiber reinforced polymer (CFRP) sheet used to strengthen structural concrete elements.