Hotel Reinforcement: Breathing New Life into a 20th-Century Gem

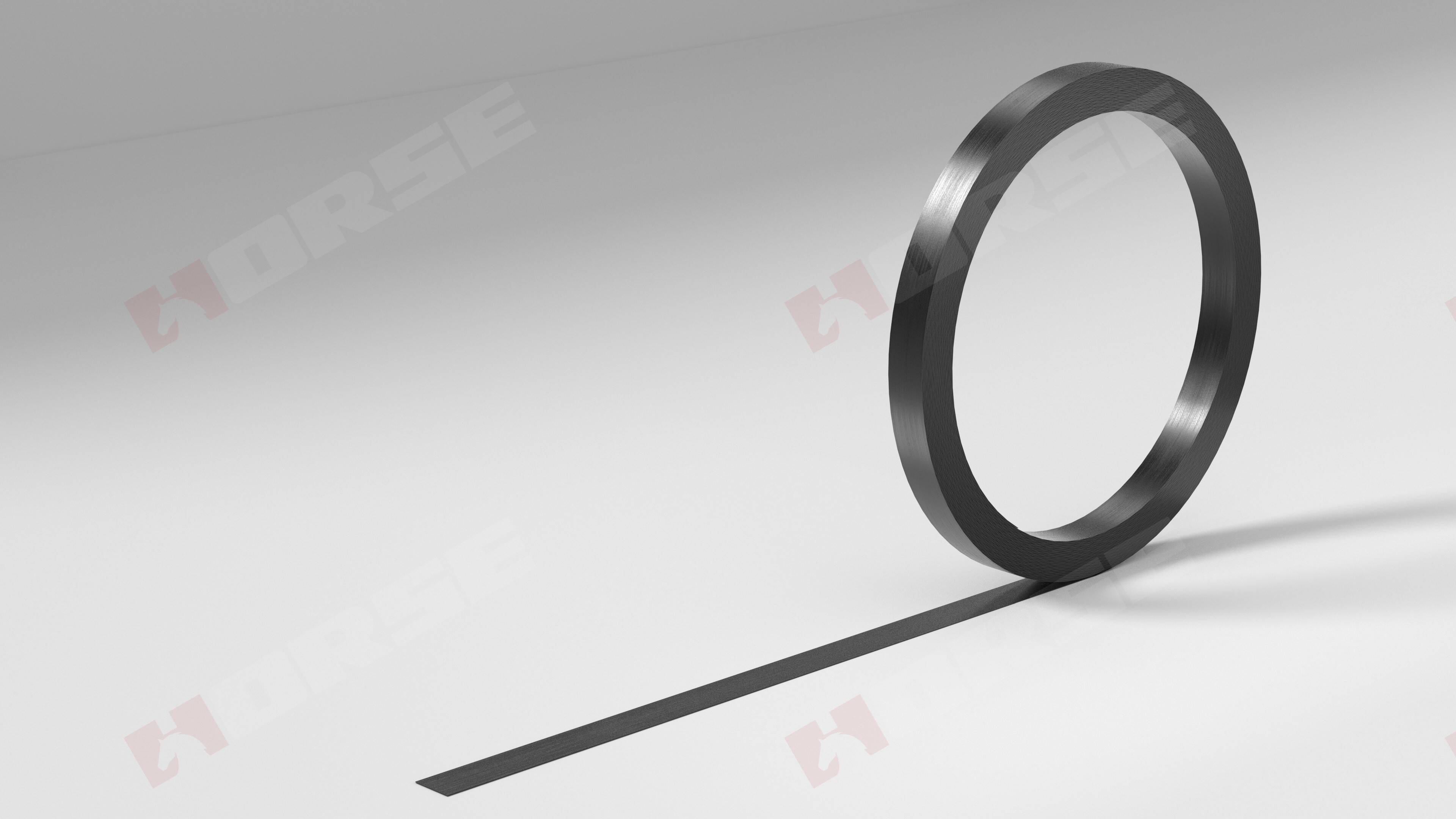

1.4mm Carbon Fiber Laminate

The core intervention centered on the application of HM-1.4 carbon fiber laminates to the building’s slabs—a choice driven by the material’s exceptional mechanical properties and compatibility with heritage structures.

Nestled within Portugal’s rich architectural tapestry, a residential building with roots dating back to the early 1900s has undergone a remarkable transformation, transitioning from a historic dwelling to a vibrant hospitality space. This metamorphosis, however, was not merely a cosmetic upgrade—it demanded a meticulous structural reinforcement effort to ensure the century-old edifice could meet the rigorous demands of its new role as a hotel.

As key contributors to this restoration initiative, our team focused on delivering a reinforcement solution that balanced preservation of historical integrity with enhanced structural performance. The core intervention centered on the application of HM-1.4 carbon fiber laminates to the building’s slabs—a choice driven by the material’s exceptional mechanical properties and compatibility with heritage structures.

Unlike traditional reinforcement methods such as steel plating, which can add significant weight and risk altering the building’s original geometry, HM carbon fiber laminates offer a lightweight yet robust alternative. Their high tensile strength (exceeding 3000 MPa) and modulus of elasticity make them ideal for strengthening slab systems, which bear critical loads in hospitality settings—from guest occupancy and furniture to mechanical equipment and dynamic foot traffic. Additionally, the laminates’ thin profile (typically 1.4 mm per layer) minimizes disruption to the building’s interior spaces, preserving original architectural details such as moldings, ceiling heights, and floor finishes that define its historical charm.

Our approach began with a comprehensive structural assessment, leveraging advanced non-destructive testing (NDT) to map the condition of the existing slabs, identify stress points, and calculate load-bearing requirements for the hotel’s intended use. This data informed a tailored reinforcement design, specifying the optimal placement, thickness, and orientation of the HM carbon fiber laminates to target areas of reduced structural capacity.

After surface preparation to ensure adhesion, the carbon fiber laminates were impregnated with epoxy resin and bonded to the slab surfaces, forming a composite system that works in tandem with the original concrete. This synergy enhances both flexural and shear resistance, effectively upgrading the slabs to accommodate the increased live loads and dynamic forces associated with hotel operations—from guest rooms and corridors to communal spaces and amenities.

The success of this reinforcement project lies in its ability to achieve three critical objectives. First, it ensures structural safety, with the upgraded slabs now compliant with modern building codes and capable of withstanding the demands of their new use over the long term. Second, it enables functional adaptation, allowing the historic building to seamlessly transition into a hotel without compromising on space, comfort, or operational efficiency. Finally, it preserves architectural heritage, avoiding the need for extensive demolition or heavy-handed modifications that would have eroded the building’s historical character.

In essence, this project exemplifies how innovative structural engineering can breathe new life into aged buildings, bridging the gap between past and present while ensuring they remain safe, functional, and relevant for generations to come.